Ref. No.:SKINPASSMILL210301

YEAR:1985, 1986,

Qty:1 Second-hand skin pass mill

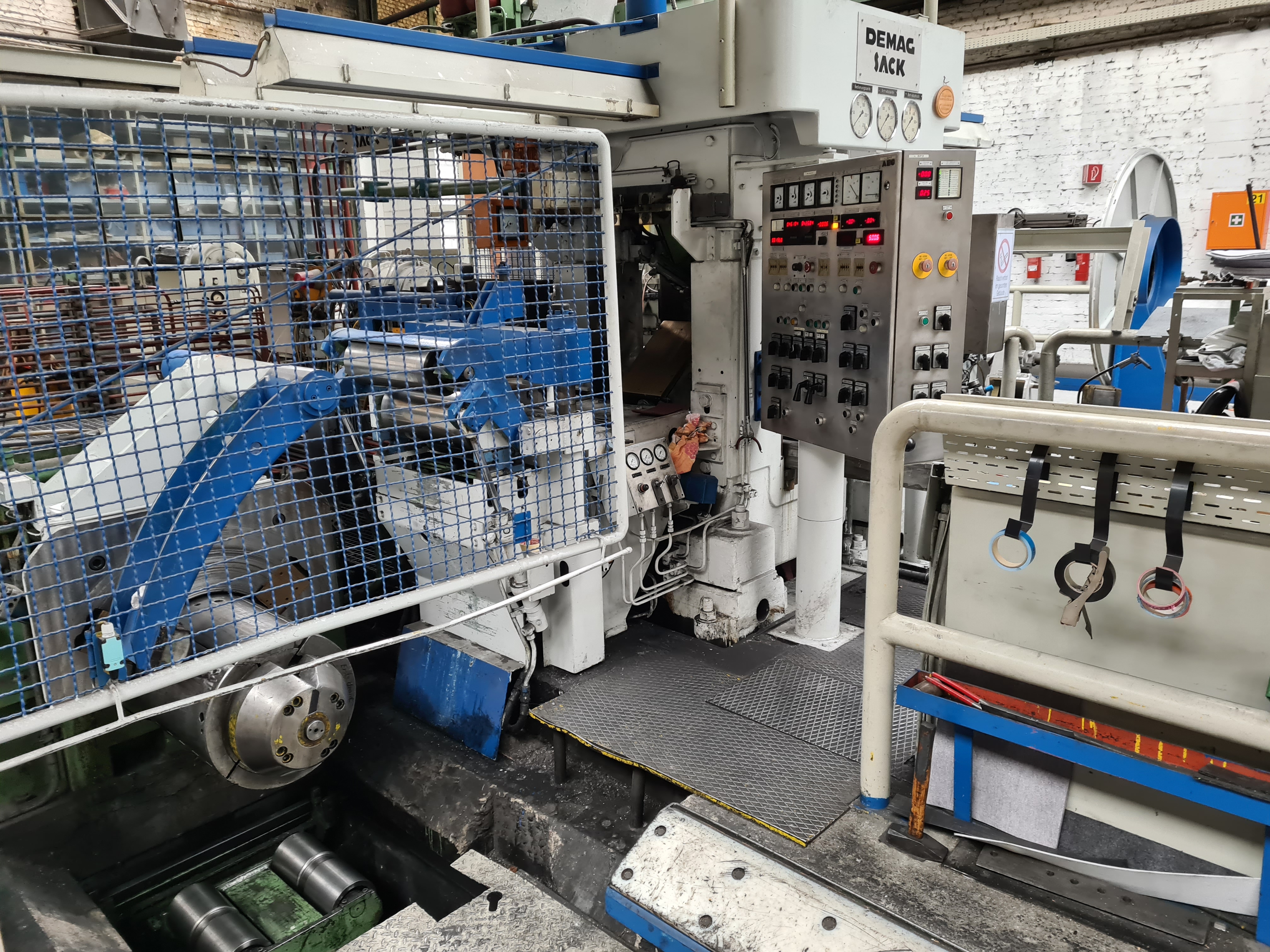

| Description | SKIN PASS MILL - DUO MILL - 80-470 MM - 4.0-0.2 MM |

| Ref. No. | SKINPASSMILL210301 |

| Year | 1985, 1986, 1993 |

| Brand | MANNESMANN DEMAG |

Qty. 1 Second-hand skin pass mill | |

| Mfc. | Mannesmann Demag Sack Built |

| Type | Duo Cold Rolling Mill – Non-Rev. Dia. 330 x 500 mm |

| Material | Carbon steel, cold rolled and annealed |

| Strip width | 80 - 470 mm Thickness entry |

Decoiler Modernised in 1986 | |

| ID | 400 with segments 500 & 600 mm Spreading range |

| Strip tension | 1300 – 65 daN Braking system |

| Braking torque | max. 1300 daNm De-coiling speed |

| Coil cross section | 20 – 1880 mm² Coil weight per mm strip width max. |

| Coil weight | 5.0 T Coil ID |

| Roll dia. | 300 – 330 mm Roll length |

| Roll force | 1850 – 2400 kN Min. roll force |

| Hydraulic roll adjustment Adjustment stroke | 80 mm |

| Adjustment speed | 1 – 3 mm/sec. Rolling speed |

| PLC system | Siemens |

| Coiler | |

| Coil ID | 400 mm with segments |

| Strip tension range I | 2500 – 25000 N Motor power |

| Strip tension range II | 500 – 2500 N Motor power |

| Gear ratio | i = 14.66 Lubrication |

Decoiler Modernised in 1986 | |

| ID | 400 with segments 500 & 600 mm Spreading range |

| Strip tension | 1300 – 65 daN Braking system |

| Braking torque | max. 1300 daNm De-coiling speed |

| Generator power | 2 x 16 kW Motors in parallel arrengement |

1 Motor can be decoupled by gear shifting | |

| Generator revolution | 0-405/2025 Transverse displacement |

Modernisation in 1993 | |

Hydraulic roll adjusting device | |

Adjustment by position and roll force-controlled hydraulic cylinder arranged on the stands. | |

Control via fast acting servo valves. | |

Strip thickness control | |

Consist of the electrical cubicle (1600 x 1600 x 600 mm) with all necessary supply units provided | |

for the following types of control | |

Position control Roll pressure regulation Return regulation (analog/digital) | |

Degree of skin pass measurement Degree of skin pass regulation | |

Qty. 2 Positioners Qty. 2 hydraulic-electric converters for measuring the rolling force | |

1 Exit guiding system (left side of the rolling mill) | |

The exit guide is equipped with the following devices | |

Base support with table top and places for tape thickness measuring device, tape greasing roller | |

and skin pass level measuring device, hydraulically adjustable folding table, hydraulically | |

operated crop shear with angled cut upper knife, loose deflection roll, bearing of the deflection | |

roll intended to accommodate a strip tension measuring device. | |

1 Oscillating cleaning device of the top roll | |

1 Oscillating cleaning device of the bottom roll Coiling station | |

| 1 Coiler shift gear | |

With 2 input shafts, helical gears, hardened and grinded, shafts mounted in roller bearings, | |

pneumatically operated gear shift stage for belt tension changeover, lubrication of the gear unit | |

by an attached oil lubrication pump, toothed clutches to connect the motors with the gear unit, | |

pneumatically operated disc brakes as idle brakes. | |

| 1 Take-up drum | |

In flange design, hydraulically operated, clamping device to grasp the beginning of the strip | |

separately controlled, cylinder with circumferential oil supply, cast steel attachment segments to | |

increase the diameter from 400 to 500 mm | |

| 1 Coil pushers | |

Hydraulically operated coil pusher with spring-loaded belt scrapers, attachment to the winding | |

gear, guide in round bars. | |

1 Strip pusher Hydraulically operated | |

| 1 Paper unwinder | |

For unwinding interlayer paper, winding shaft mounted in roller bearings, set up for tensioning | |

paper rolls, braked by a pneumatically operated disc brake | |

| 1 Coil lifting car | |

With hydraulically operated lifting and driving device as well as tilting device and movable pit | |

lock, coil holding device for narrow coils, hydraulically swiveling and hydraulically adjustable to | |

| strip width. | |

| 1 Coil magazin | |

For holding 3 coils of max. width and min. coil diameter of 800 mm, coil magazine made of | |

welded construction anchored in the foundation and provided with a polyamide or wooden | |

| support | |

| 2 Joint spindles | |

including rolls and pinion sleeves for driving the rolls, arranged between the pinion gear and | |

the rolls, support device for the joint spindles when changing rolls, the support is hydraulically | |

| operated | |

1 Hydraulic balancing for the above roll installation unit | |

1 Cushioning plate arranged in a tilting gutter for coil cushioning | |

4 Wear strips for mounting in the stand windows | |

16 Wear strips for the chocks | |

1 Transfer tables of the unwinding deflection roll stand | |

Shortening of the table and renewal of the hydraulic cylinder as well as attachment of a console | |

to accommodate the skin pass degree measuring device | |

1 High pressure hydrauli aggregat | |

For supplying and controlling the adjusting cylinders, designed for an operating pressure of | |

250 bar, nominal pressure 315 bar, | |

the hydraulic unit consists of | |

oil tank, pump station and additional reserve pump, filter station and valve stand, the system is | |

internally piped, the valves are wired | |

1 Hydraulic aggregat with valve stand | |

To supply and control all hydraulic cylinders within the existing assemblies described above | |

(without unwinding station) | |

The unit is designed for an operating pressure of 100 bar, nominal pressure 120 bar and | |

| consists of | |

oil tank, pump unit and additional reserve pump, filter station and ventlistand, control by | |

electro-magnet valves, the system is internally piped and the valves are wired. |